🎵 D-M-A-I-C, that’s just the tool for me

To solve problems and boost efficiency

It’s D-M-A-I-C! 🎵

One of our super powers as Business Analysts is the ability to solve problems in a structured and efficient way. And we do this by using a dynamic range of tools and methodologies. The one we want to learn about today is Lean Six Sigma, a powerful method to make meaningful improvements in how a business operates. It might look like it but Lean Six Sigma doesn’t have to be complicated.

We’ve all been there: stuck in a project that’s going nowhere, or trying to fix a process that seems broken beyond repair. Maybe the initiative started before you joined, or progress has stalled, and now everyone’s asking, “How do we actually move forward?”

That’s where DMAIC (pronounced dee-may-ik) comes in: a structured, data-driven method for solving problems and achieving measurable results.

In this post, we’ll break down the five stages of DMAIC and show you how to apply them to any business process so you can deliver better outcomes for your customers, stakeholders, and team.

What Is DMAIC?

DMAIC is a structured, data-driven improvement cycle used in Lean Six Sigma to optimize existing business processes. It stands for:

- D – Define

- M – Measure

- A – Analyse

- I – Improve

- C – Control

Think of it as a roadmap: each step helps you move from identifying a problem to implementing and maintaining an effective solution.

Step 1: Define – Clarify the Problem and Set Objectives

The Define phase is about understanding the project at a high level and setting clear objectives. It establishes the scope, goals, and boundaries of the improvement effort.

How to go about it:

- Clearly articulate the problem statement: What exactly is going wrong?

- Identify the project scope: What processes are included and what falls outside?

- Establish project goals and measurable objectives: These provide benchmarks for evaluating improvement.

- Identify key stakeholders: Who is impacted, who can influence outcomes, and who needs to be kept informed?

- Define a timeline and resources: What is achievable within the constraints of time, budget, and personnel?

The Define phase ensures everyone has a shared understanding and prevents misalignment later in the process.

Step 2: Measure – Collect Data and Establish a Baseline

The Measure phase focuses on gathering quantitative and qualitative data to understand the current performance of the process. The aim is to create a reliable baseline against which improvements can be measured.

What does this mean in practice?

- Document the current process flow: Use process maps, flowcharts, or SIPOC (Suppliers, Inputs, Processes, Outputs, Customers) to capture every step and interaction.

- Identify key performance indicators (KPIs): Determine what metrics best represent process efficiency, quality, or customer satisfaction.

- Develop a data collection plan: Decide what data is needed, how it will be collected, and who will collect it.

- Quantify process capability: Understand how consistently the process meets performance standards.

- Establish a baseline measurement: Provides a starting point for comparison after improvements are implemented.

This phase turns vague assumptions into measurable facts, which are essential for objective decision-making.

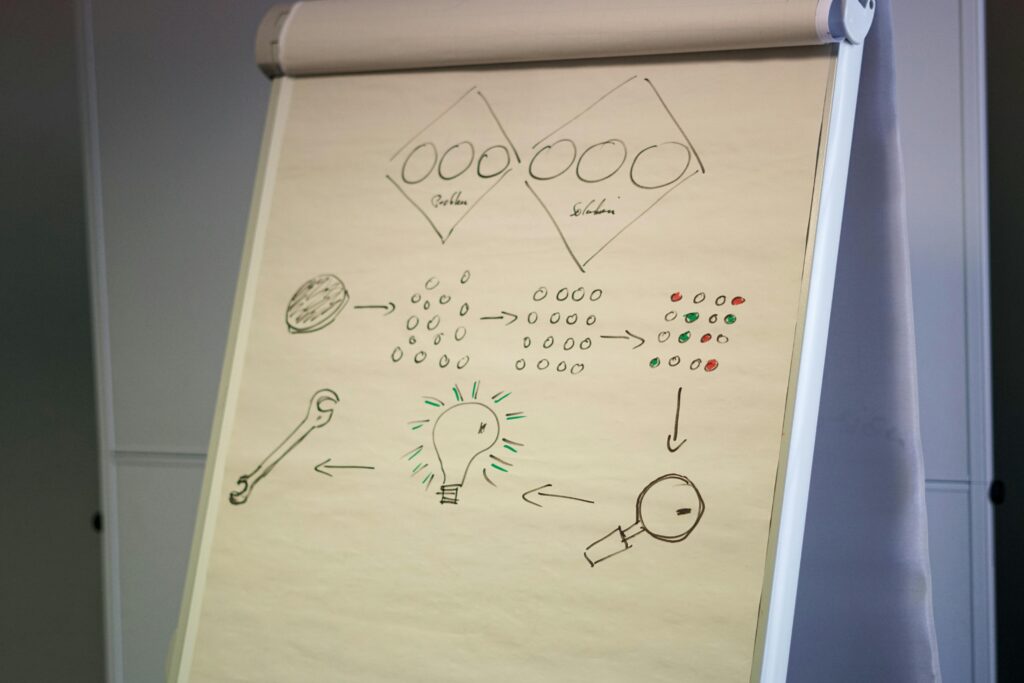

Step 3: Analyse – Identify Root Causes

The Analyse phase is where you dig deeper to discover the underlying reasons why the process isn’t performing as expected. This is critical because addressing symptoms alone will not lead to sustainable improvement.

Here’s what you should do:

- Identify patterns, trends, and correlations in the measured data.

- Use structured analysis tools such as Fishbone (Ishikawa) Diagrams, Pareto Charts, or scatter plots to visualize and prioritize causes.

- Apply techniques like 5 Whys to drill down to the root cause of each identified problem.

- Distinguish between common causes (systemic issues) and special causes (isolated events).

- Validate potential causes with data rather than assumptions: Correlation does not always imply causation.

- Prioritise root causes based on impact and controllability to ensure the team focuses on the most critical areas first.

The Analyse phase transforms data into actionable insights and provides a roadmap for targeted improvements.

Step 4: Improve – Develop and Implement Solutions

The Improve phase focuses on designing, testing, and implementing solutions to address the root causes identified in the Analyse phase. The goal is to enhance process performance in measurable ways.

Your plan of action will look like these:

- Brainstorm potential solutions or process changes in a structured manner.

- Evaluate solutions using criteria such as impact, feasibility, and cost-effectiveness.

- Conduct pilot tests or simulations to validate effectiveness before full-scale implementation.

- Optimise the process by streamlining steps, eliminating waste, and reducing variability.

- Monitor immediate results and make adjustments as needed during implementation.

- Ensure that the process changes are aligned with organisational goals and stakeholder expectations.

The Improve phase is about turning insights into practical, measurable action.

Step 5: Control – Sustain the Gains

The Control phase ensures that the improvements achieved are maintained over time and that the process does not revert to its previous state. It institutionalises changes and establishes mechanisms for continuous monitoring.

Effective ways to do this include:

- Develop Standard Operating Procedures (SOPs) and documentation for the improved process.

- Create monitoring systems such as dashboards or control charts to track key metrics in real time.

- Assign ownership and accountability to individuals or teams responsible for maintaining performance.

- Implement training programs to ensure staff understand and follow the improved process.

- Establish a review schedule to periodically check performance and adjust processes if needed.

- Promote a culture of continuous improvement, encouraging employees to identify further opportunities for enhancement.

The Control phase ensures long-term sustainability, making the process resilient, repeatable, and adaptable.

Benefits of the DMAIC Methodology

Using DMAIC will help to:

- Streamline workflows

- Eliminate waste and errors

- Improve productivity and morale

- Enhance customer experience

- Build a culture of continuous improvement

By following the Define–Measure–Analyse–Improve–Control framework, you can support your organisation to transform inconsistent processes into efficient, scalable systems.

Conclusion

DMAIC isn’t just another tool, it’s a mindset for structured problem-solving. Whether you’re in manufacturing, healthcare, customer service, or IT, this method can help you achieve measurable, lasting results.

So next time you’re facing a process challenge, remember:

🎶 D-M-A-I-C — that’s the tool for me! 🎶